ExoSOLS

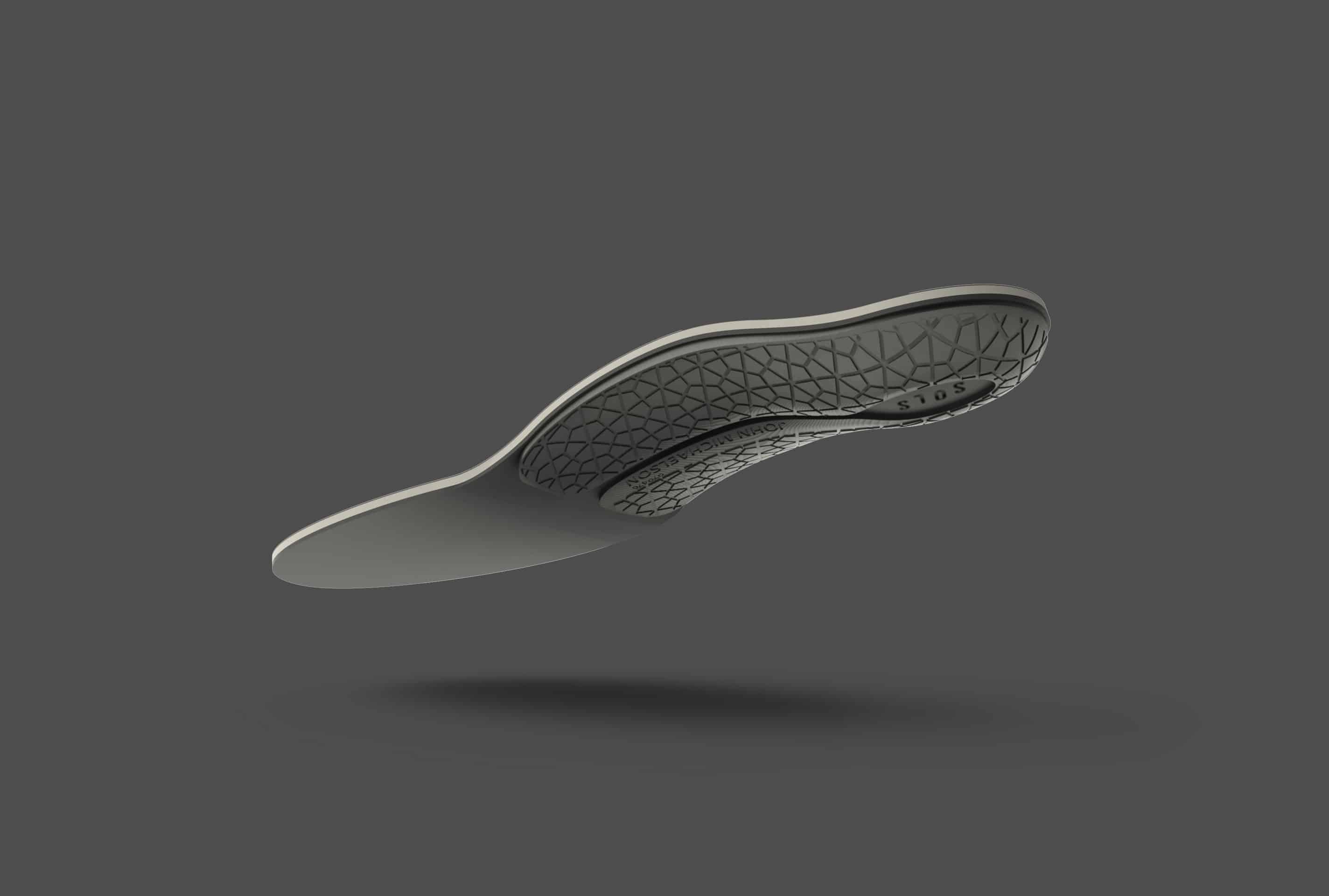

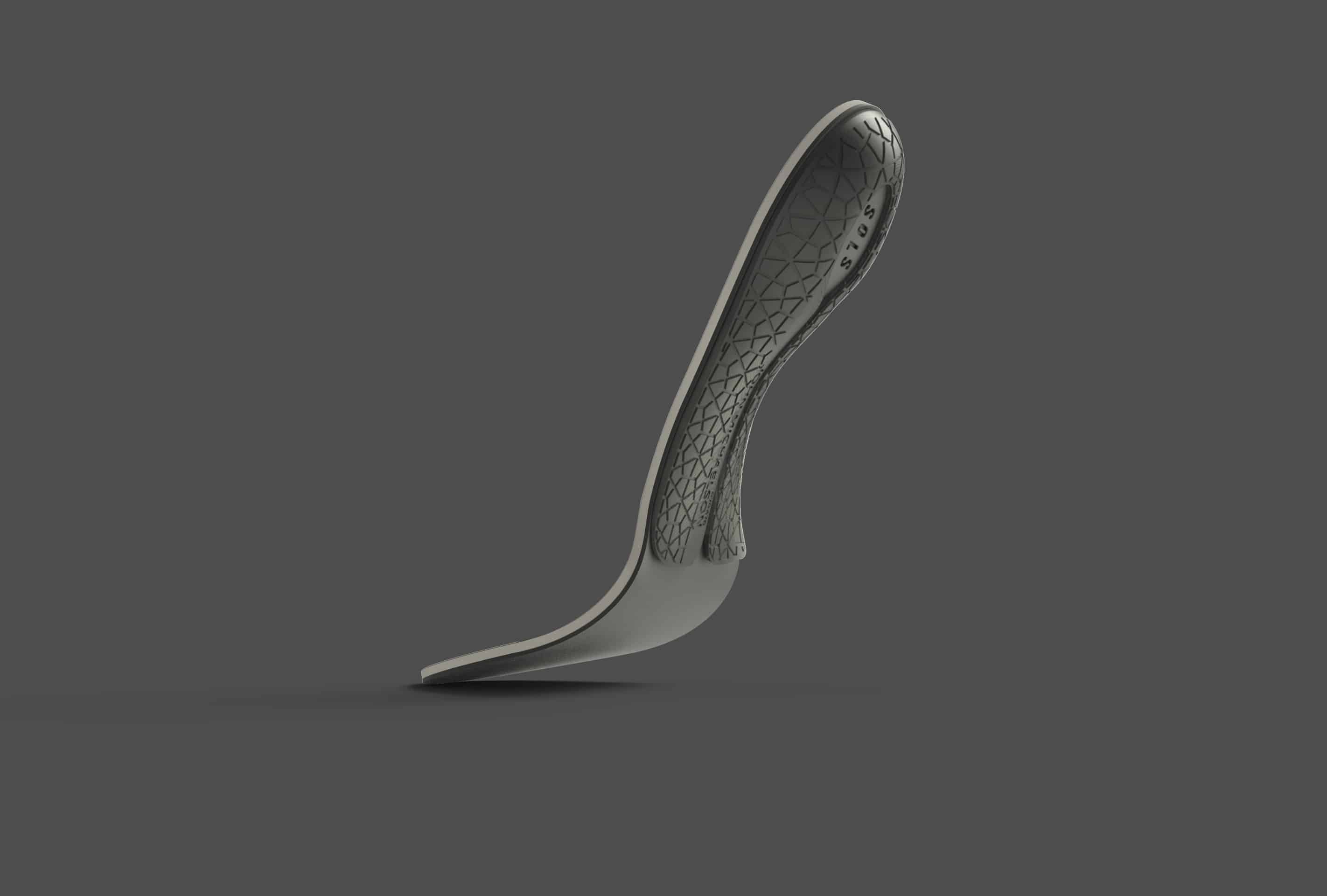

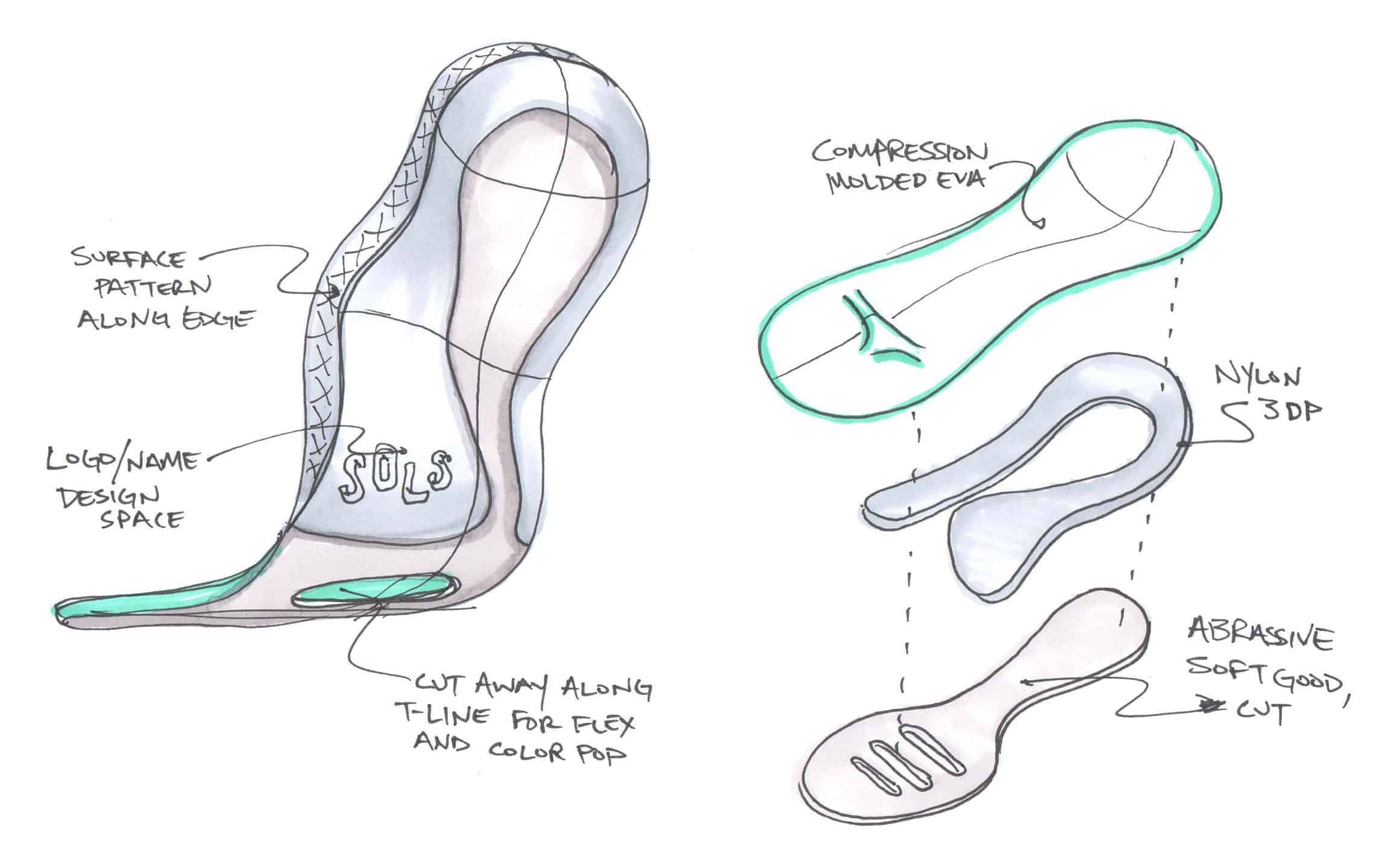

ExoSOLS are 3D Printed custom orthotics that I designed for SOLS. The product combines a 3D printed nylon base that supports your foot with multiple layers of compression molded foam to provide comfort.

I lead the conceptual design as well the design direction. I collaborated with Sols's Biomechanical Engineering team to prototype and refine the design, and worked with their CAD Engineers to define the design for production.

After creating a successful medical prescriptive orthotic, SOLS was looking to enter into the consumer market and tapped me to lead the product design efforts. As a starting point, I used SOLS database of feedback it had collected from their network of podiatrists who prescribe their medical product. I then produced a wide range of concepts that were inspired by the recurring feedback, and built around the experience I was hoping to create for the consumer market version of SOLS.

One of the continual pieces of feedback that became a driver of the design was with fitting the wide range of shoes that people have. The SOLS engine's algorithms create unique CAD models with surfaces that fit custom to the purchaser's foot with excellent precision. I combined those ideal surfaces with the U-shaped base to provide Exo SOLS with the flexibility to fit in any shoe. By strategically varying the thickness of the 3D printed nylon material I could create a design that provides the wearer with the support and the flexibility they desire.

Like all of my projects, this started out with sketching concepts with markers, pen, and paper. This is the best way to quickly ideas out and communicate them with the team. From there I worked with Sols's Biomechanical Engineerings to make quick prototypes of the sketches by chopping up older SOLS and combining them with different materials and testing them around the office. Next we created CAD models of the designs that worked best. Since SOLS are 3D printed, we were able to prototype and test these models by 3D printing in the actual material they'd be produced in. This allowed us to cycle through design refinements much quicker and with more confidence than is typical in product design.

To narrow down our prototypes we ran tests with pressure sensors to find out which concepts provided the most relief. Once a direction was chosen, I worked with Sols's CAD Engineers to to refine the design direction as they defined it in code.

Exo SOLS were just released to the public last month, and so far the feedback has been very positive. Designing for SOLS is particularly exciting because it is a mass-customized product. When going to production my designs don't get cut into steel tools for molding, instead they get written into code that becomes a unique 3D printed object every time the product is ordered.

Love this idea!