Petal Pegs

Petal Pegs was a university project developed whilst I was studying at Central Saint Martins, as part of a live brief with homeware company Joseph Joseph.

Clothes pegs are not intuitive objects to organise around the domestic space; they are easily lost and often left in redundant spaces.

The final design was one of the solutions to solve everyday frustrations in the domestic space.

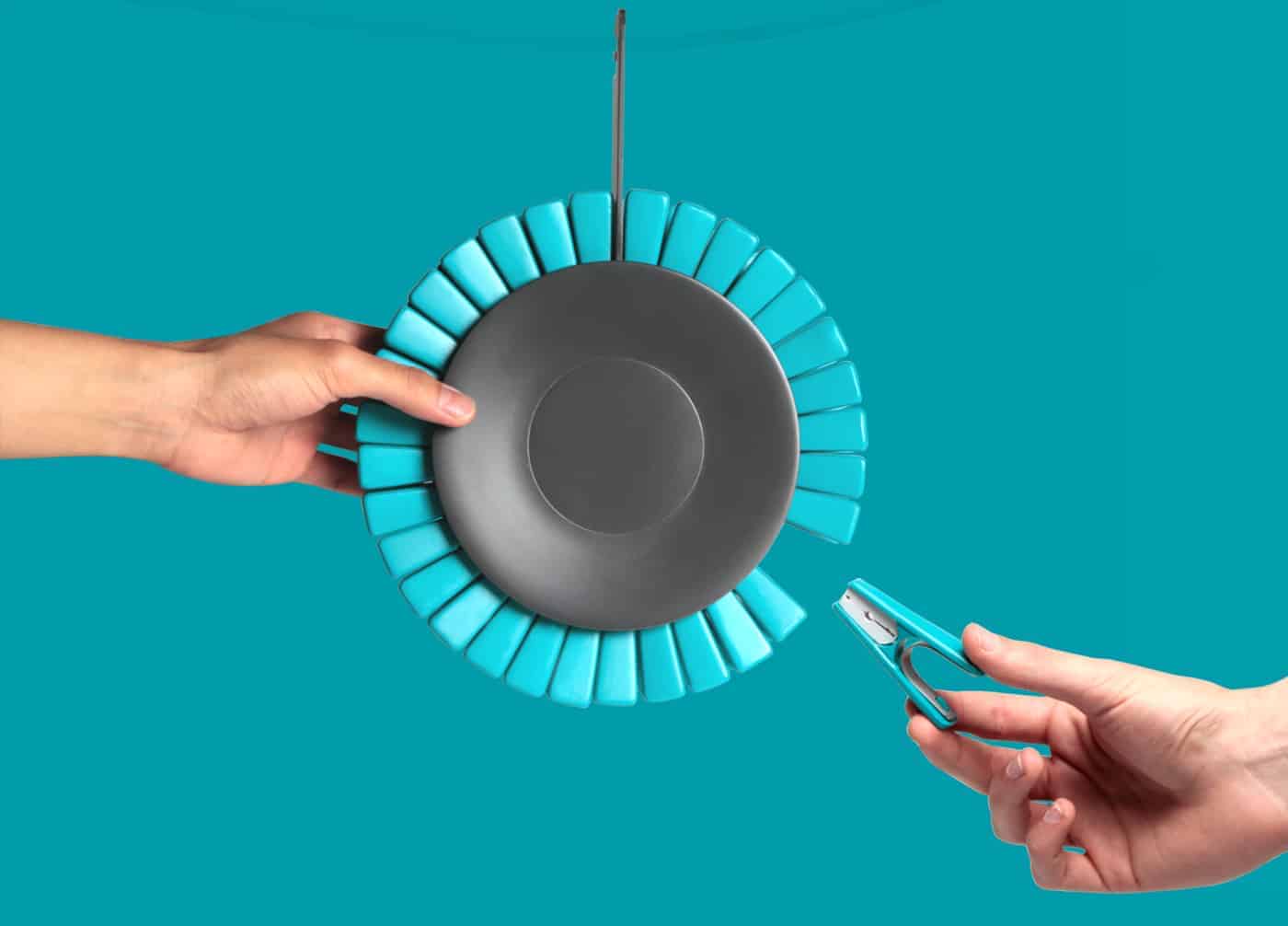

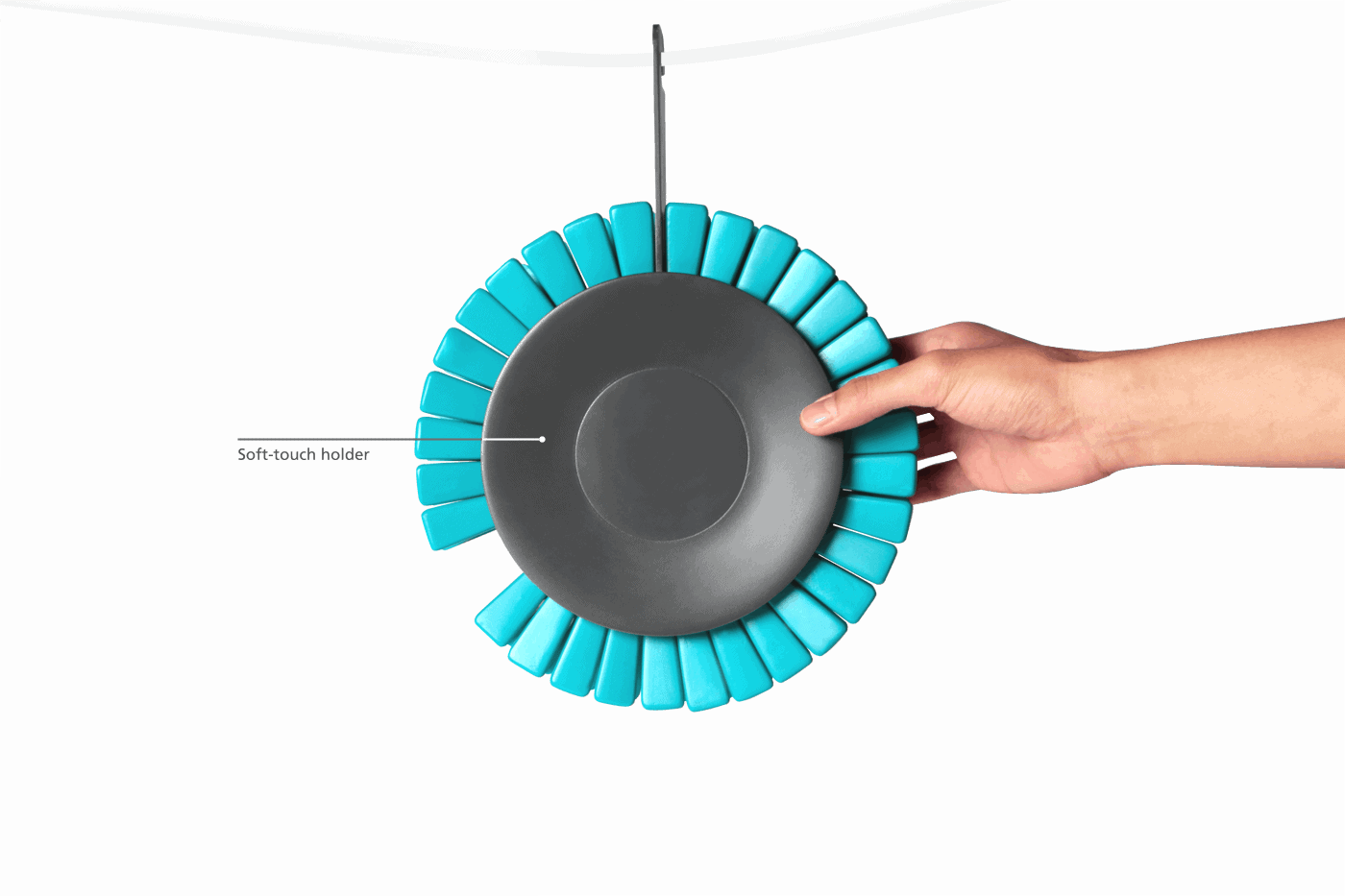

As a way of storing pegs, Petal Pegs encourages organisation and turns a mundane task into something rather satisfying.

I came up the idea through user-centered ethnological research of finding problems in real-life habitats in friends and family's domestic spaces. I started in the kitchen but early realised that Joseph Joseph has already solved many frustrations in this area. This has lead me to observe user-behaviours in other parts of the house such as the laundry area.

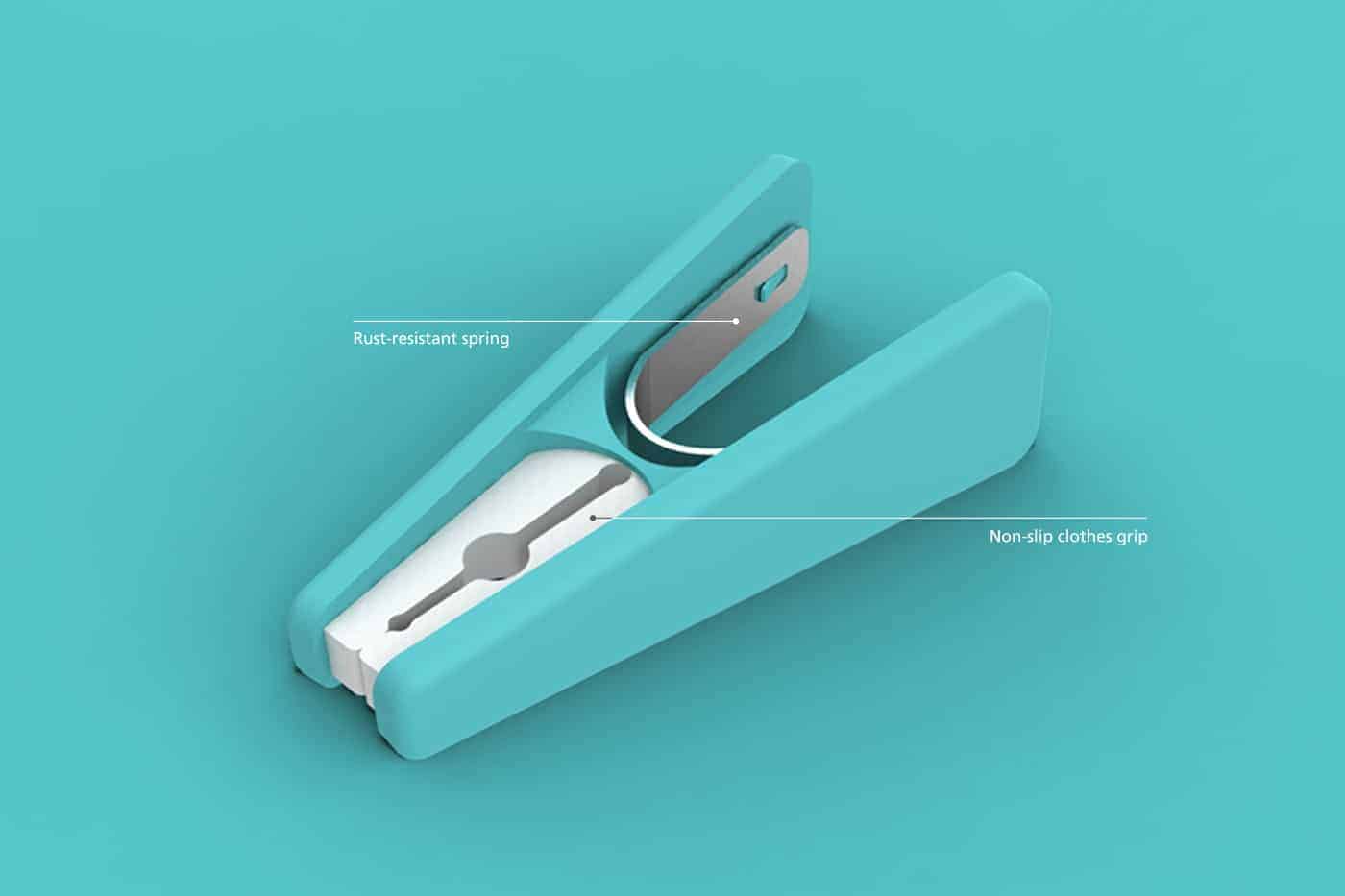

The material was chosen through brand values, existing Joseph Joseph products and the main function of a clothes pegs, which is the 'hinge' part of clothes pegs. I thought that it was a good opportunity to investigate new materials and its applications. If you think about Joseph Joseph's first successful product, the folding chopping boards, which allows the user from chopping and then transferring all the chopped food to either the saucepan or the bin, they have used Polyropylene (PP) which has an integrated hinge, this gives a unique aesthetic whilst keeping the function unique to the user.

One of the main problems of current clothes pegs are its storing, you often loose them and mix them up with other wooden or other old mouldy ones. The hinges, grips and springs were also the other frustrating parts of conventional clothes pegs, the springs are commonly made out of metal, causing rusting resulting from acid rain, leading to rusts getting in contact with your clean white clothes, I have decided to use sprung stainless steel for the spring and white silicone rubber for the grip to prevent your clothes from falling on the ground when there is strong wind and recieving discolouration from the grip.

The eureka moment was realising the relationship between the product's form and its function. All together, the pegs formed the shape of a flower, which is commonly thought of as attractive, fresh and eye-catching.

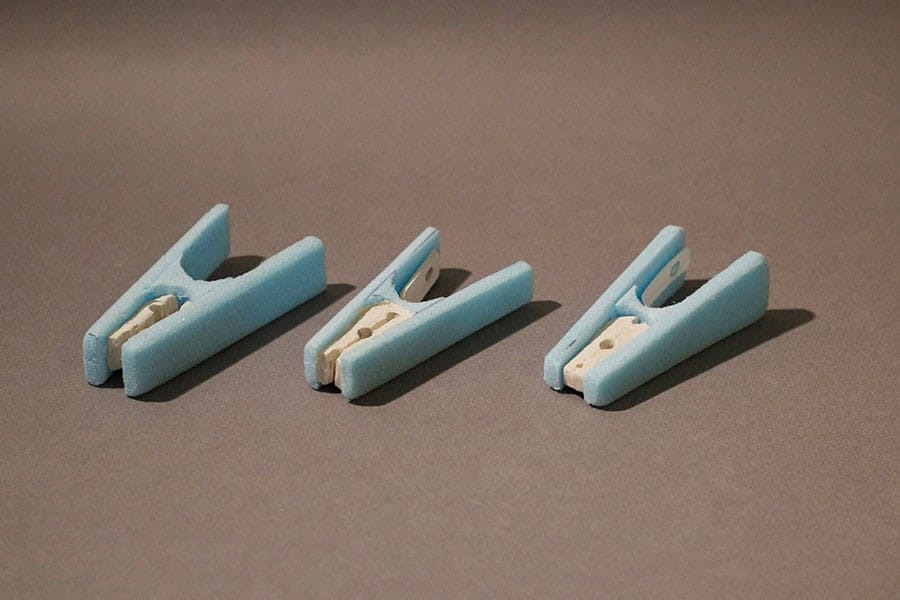

I used various tools from sketching early ideas, refining concepts through iterative 3d sketching forms, foam-modelling details, quick sketches using clay, lathing chemi-wood for the caddy, laser-printing the logo, creating the plastic part of the clothes pegs through silicone moulding to developing / rendering 3D on the computer. For the packaging, I used a laser-printer to create the die-cut and spray mount the branded graphics on top.

The project was displayed in my final year of university. Seeing that the prototype was not actually working as normal pegs, people were pinching the model and breaking them. I guess I took it as a compliment, I remember keeping a super glue just incase somebody would try and use the prototype.

I learned many things from this project. It had a massive impact in my career. I now work for Joseph Joseph after 2 years of graduating.

I love it!